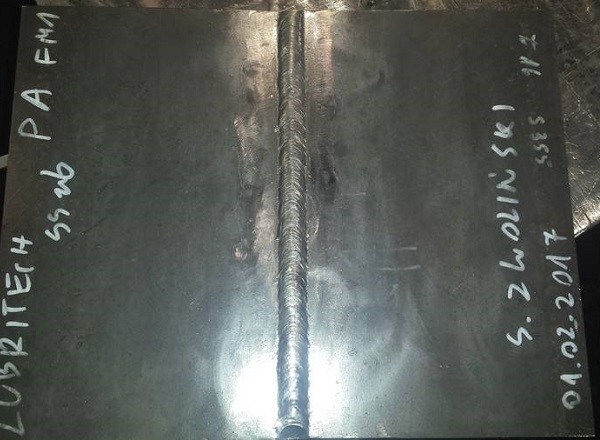

Why buy? Better to regenerate!

Lubritech specializes in professional regeneration of parts for industrial machines and engines. Our many years of experience, skills and technological facilities allow us to perform the regeneration of the most complex elements with full precision. We direct our services to all forklift owners, regardless of make and model. Regeneration of used elements is a guarantee of reliable and safe operation for the next years, and at the same time clearly lower costs of repair and service. We provide warranty for all works performed, while providing quick service and technical assistance.

Our offer includes:

- Regeneration of injection pumps supplying the engine with fuel. Injection pumps require regeneration when they do not provide adequate pressure, so that the engine of the forklift does not run smoothly, it can lose speed or it is not possible to start it at all.

- Regeneration of turbochargers, which are one of the most vulnerable to damage elements. Solid regeneration allows the turbocharger to return to full capacity, thanks to which the forklift achieves the best performance of its work.

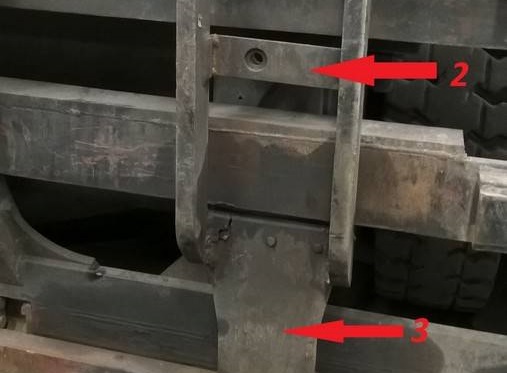

- Regeneration of transmission, thanks to which it is possible to obtain the correct torque and travel speed. A faulty gearbox is relatively easy to diagnose – it makes metallic noises, there are problems with gear shifting, or there are fluid leaks.

- Regeneration of actuators, responsible for raising and lowering loads on the forks of the truck. Actuators, subjected to very high and frequent loads, will require regeneration after some time. This action allows them to regain full operational efficiency, increasing the safety of device operation.

- Regeneration of radiators, thanks to which it is possible to maintain a safe engine operating temperature. Radiators for proper operation must be tight and unobstructed. After several years of use, scale may build up in the ducts, reducing cooling efficiency. Also, mechanical damage to the radiator can lead to leakage and, as a result, lack of engine cooling. Regeneration of radiators is the easiest way to repair them.

- Regeneration of controllers, power boards, logic cards, computers, displays and panels in forklifts, construction and manufacturing machines.

First a quote, then a service

We have OTI licenses number UD-03-73-N/2-17 and UD-03-73-P/1-13

We provide up to 12 months warranty for all services!