Forklifts are one of the more exploited machines. They are widely used in many companies with very different business profiles. The most consuming element of a forklift is its forks, which are exposed to huge loads, impacts, abrasion, corrosion and other random damage. That is why we offer a forklift regeneration service.

Realization of fork regeneration

Yes – forks can be regenerated

Yes – forks need to be regenerated

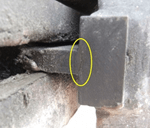

The regeneration of forks for forklifts is a process much more cost-effective than the purchase of completely new components. Regeneration prices are estimated at between 20% and 50% of the value of new forks! It is worth noting, however, that forks are not always suitable for regeneration. There is no regeneration of equipment whose consumption has exceeded 10% – this is not as unprofitable as it is dangerous. Forks are also not repaired to restore their nominal value!

Fork regeneration usually includes:

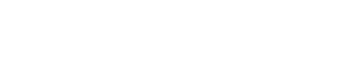

- repair and replacement of sleeves,

- replacement of damaged hooks,

- cylinder mounting

- rollers, pins, sleeves,

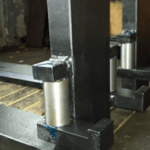

- straightening curved forks,

- replacement of hard to wear sheet of the bottom part of extendable forks,

- repair or replacement of guides.